In recognition of International Women’s Day, we’re excited to share the final installment of our…

In Case You Missed It—5 Trenchless Technology Takeaways from the Interlachen Sewer Rehabilitation Project

The North American Society of Trenchless Technology’s (NASTT) annual No-Dig Show is the largest trenchless technology conference in North America, where underground infrastructure professionals come together to learn new techniques to repair and improve infrastructure. Murraysmith + Quincy’s very own NASTT members, Brendan O’Sullivan and Rylee Archuleta, presented on the Interlachen Sewer Rehabilitation Project completed for the City of Fairview, Oregon. In case you missed it, here are five takeaways that highlight unique solutions to this project’s challenges.

1. Interlachen Trunk

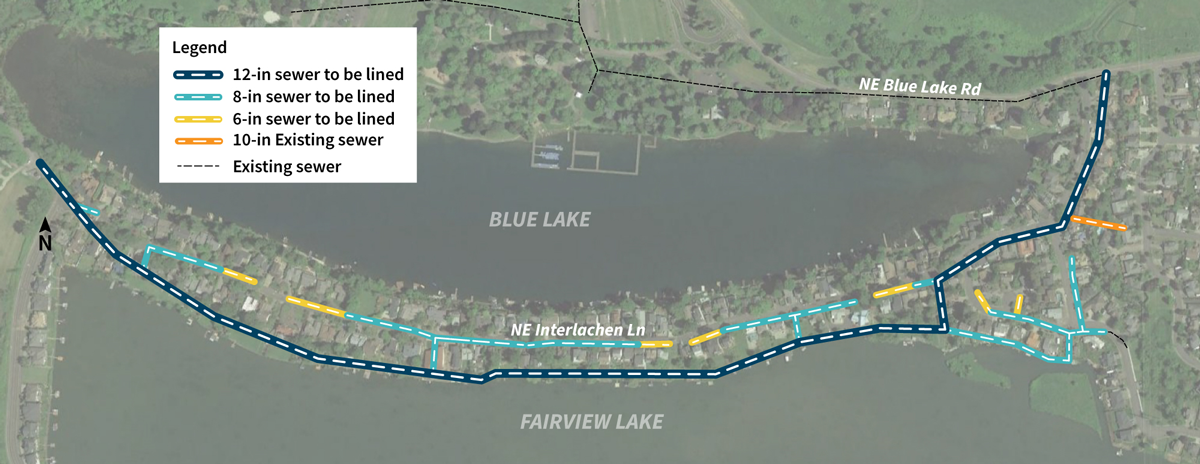

The City of Fairview’s Interlachen Trunk Sewer is a 12-inch diameter, concrete sanitary sewer system that runs through nearly 70 backyard easements along the shore of Fairview Lake. To extend the life of its system, the City decided to rehabilitate approximately 12,000 linear feet of pipe.

2. Environmental and Cultural Permitting

Because the project area was once the site of a large Multnomah Native American village called ničáqʷli, any excavation along the Fairview Lake shoreline would trigger floodplain permitting and archeological investigation. This challenging situation meant that a trenchless rehabilitation method was the best solution.

3. Ultra-Violet vs. Thermal Cured-In-Place-Pipe (CIPP)

The constructability constraints along the Interlachen Trunk provided the perfect opportunity for an innovative solution—UV CIPP lining. The small construction footprint allowed contractors to work around landscaping with minimal impacts to homeowners.

1: Interlachen Lane is very narrow in places. 2: Staged liner at the site. 3: Cable running from Interlachen Lane to backyard manhole.

4. Barging onto Site

Due to the difficult access of the lake shore manholes, some CIPP installation sites were staged and cured using a barge on Fairview Lake. The barges were loaded at a point with vehicle access, then floated to the project site.

5. Successful Rehabilitation

In the end, the Interlachen Trunk was successfully rehabilitated due to the many benefits of UV-cured CIPP. In addition to a smaller construction footprint than thermal, advantages of UV CIPP include minimal styrene emissions (less impact to residents), no discharge water to capture (less environmental risk), a stronger and thinner liner (less hydraulic impact), and less risk of excavation due to the ability to inspect and re-insert the liner prior to curing.